Services Offered

At Colbrit, we offer services in five major categories- Engineering Services, Tool & Die and Mold Making, Precision Metal Stampings, Plastic Injection Molding and CNC/EDM/Swiss Screw Machining. Though most of our customers take advantage of our ability to deliver a turnkey project from design through finished product, we also provide each of these services individually or in any combination as required.

To assure we retain total control over quality and delivery, we maintain in-house all the tools and equipment required to perform each phase of your project, without the need of relying on outside sources. However, we know that even the best equipment is not enough without the skilled hand of a master technician to run it. For that reason, all of our engineers, tool makers and technicians are thoroughly trained and experienced in all operations needed to take your project from concept to completion.

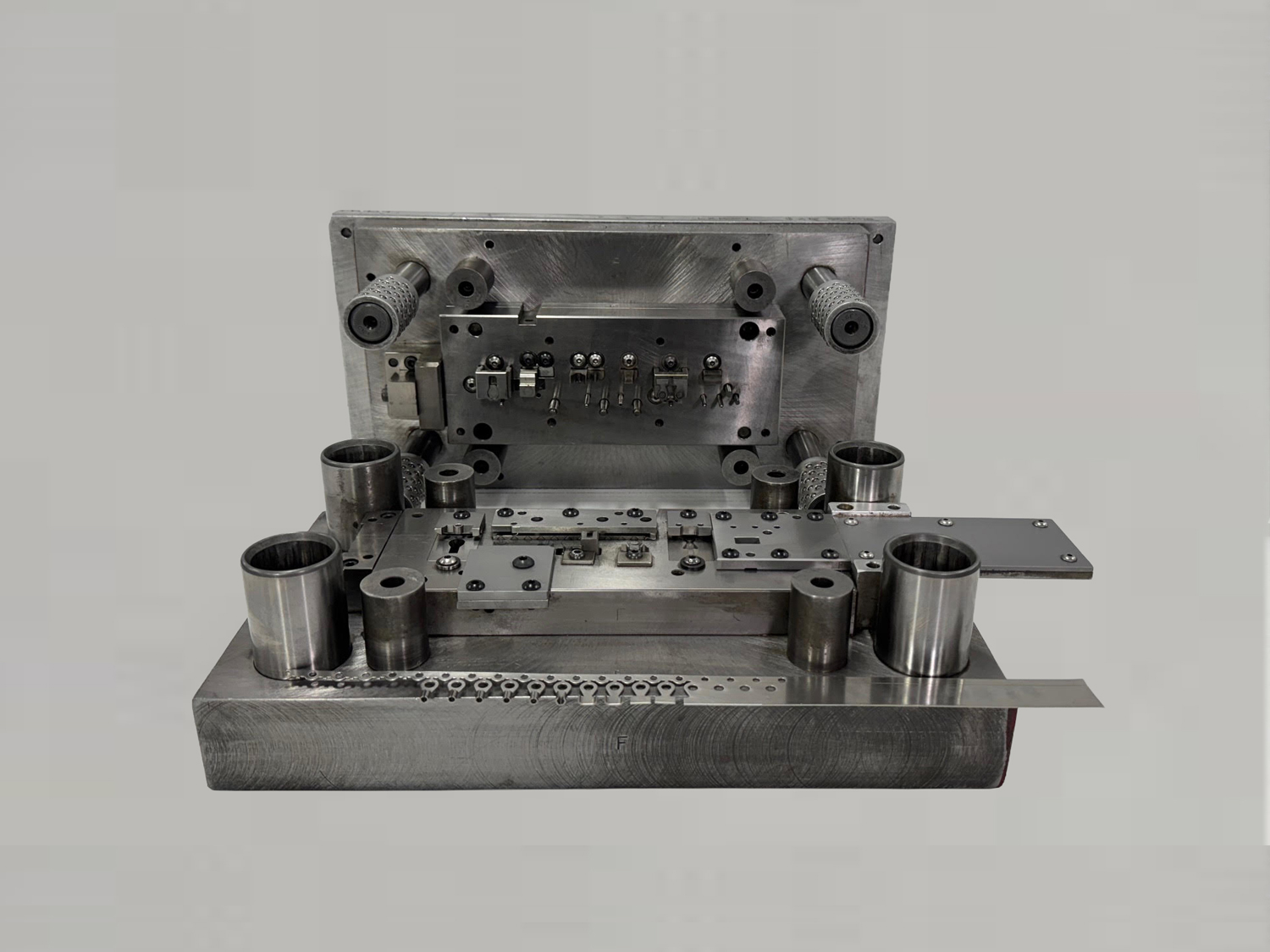

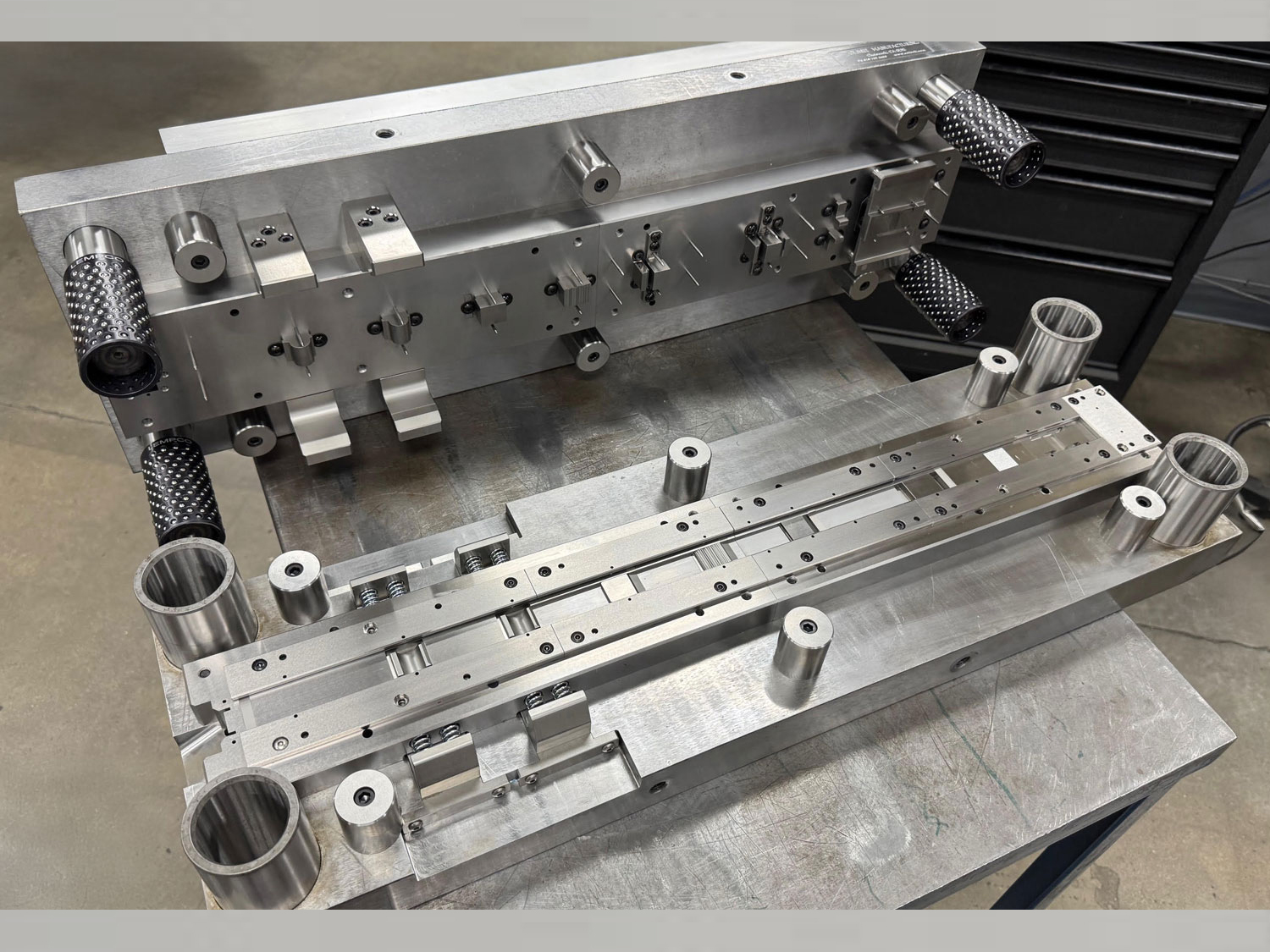

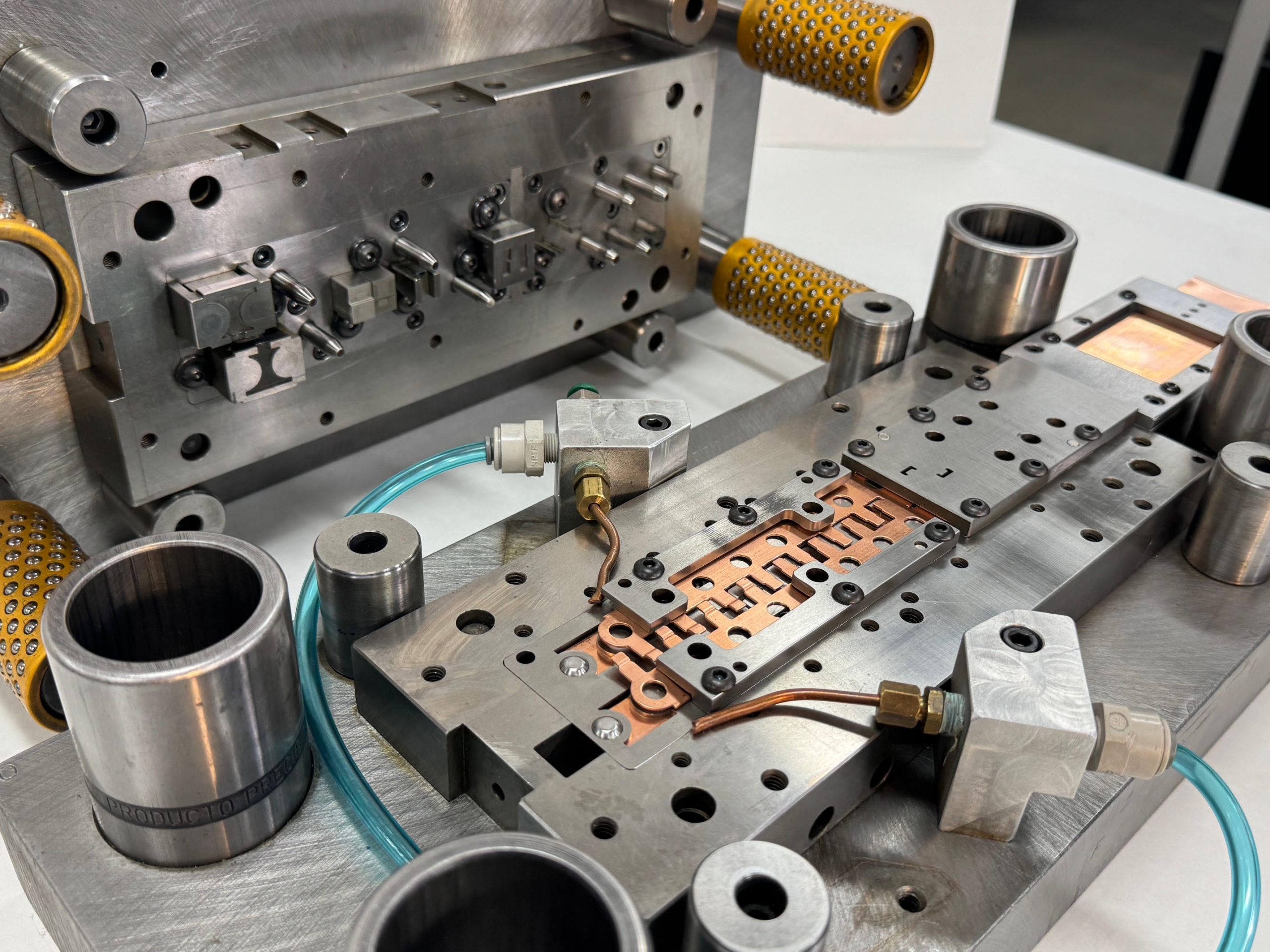

Tool & Die Manufacture

Mold Making

Depending on your requirement we can manufacture tooling from your design or we can design for you, then manufacture.

To assure your complete satisfaction, we consult closely with your engineers at every stage of your project from inception through “first article”.

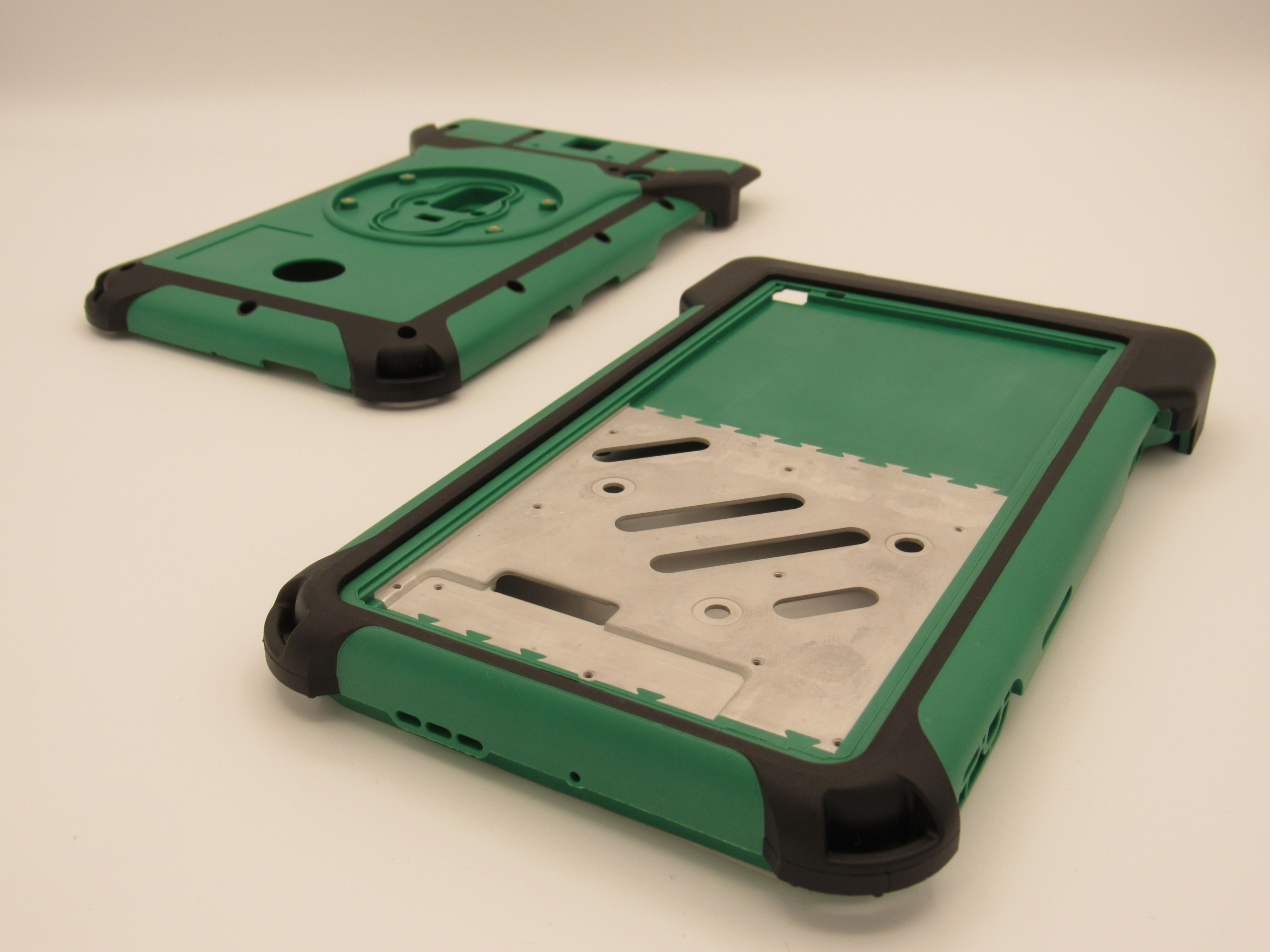

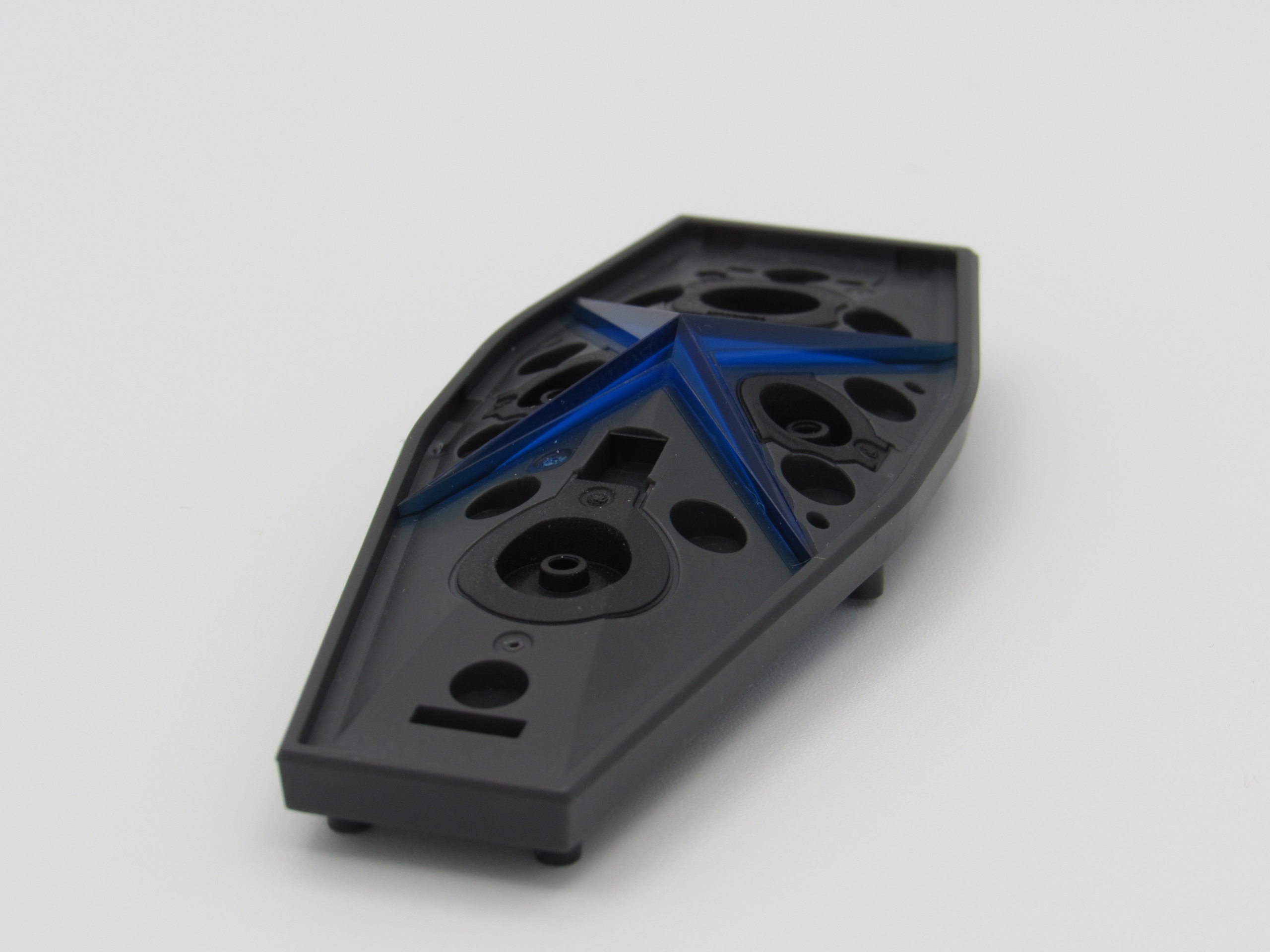

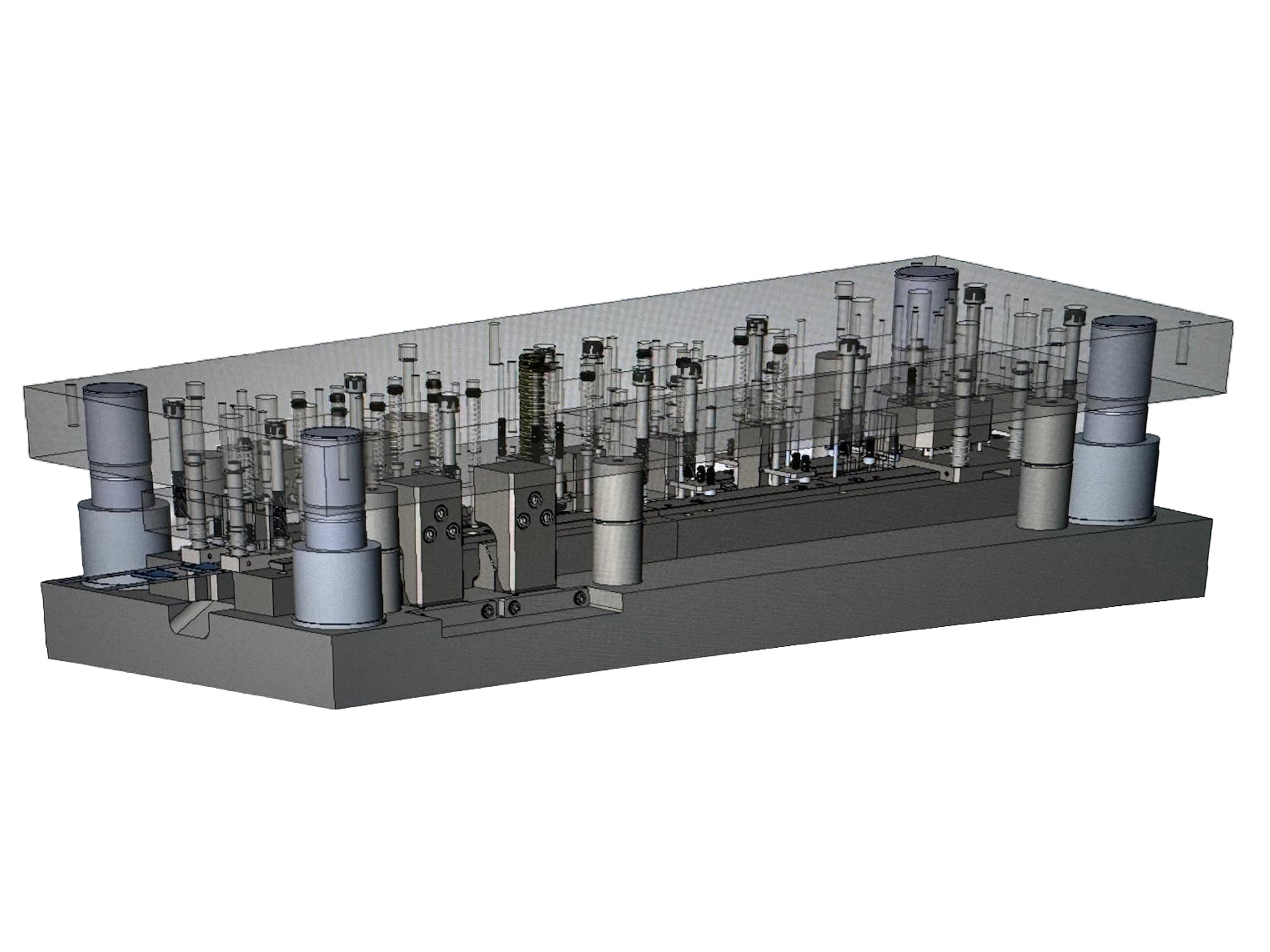

Plastic Injection Molding:

Precision Manufacturing Backed by Engineering Excellence

Colbrit now offers cutting-edge plastic injection molding services, combining expert engineering, high-quality tooling, and global manufacturing partnerships to deliver precise, cost-effective plastic components tailored to your most demanding applications.

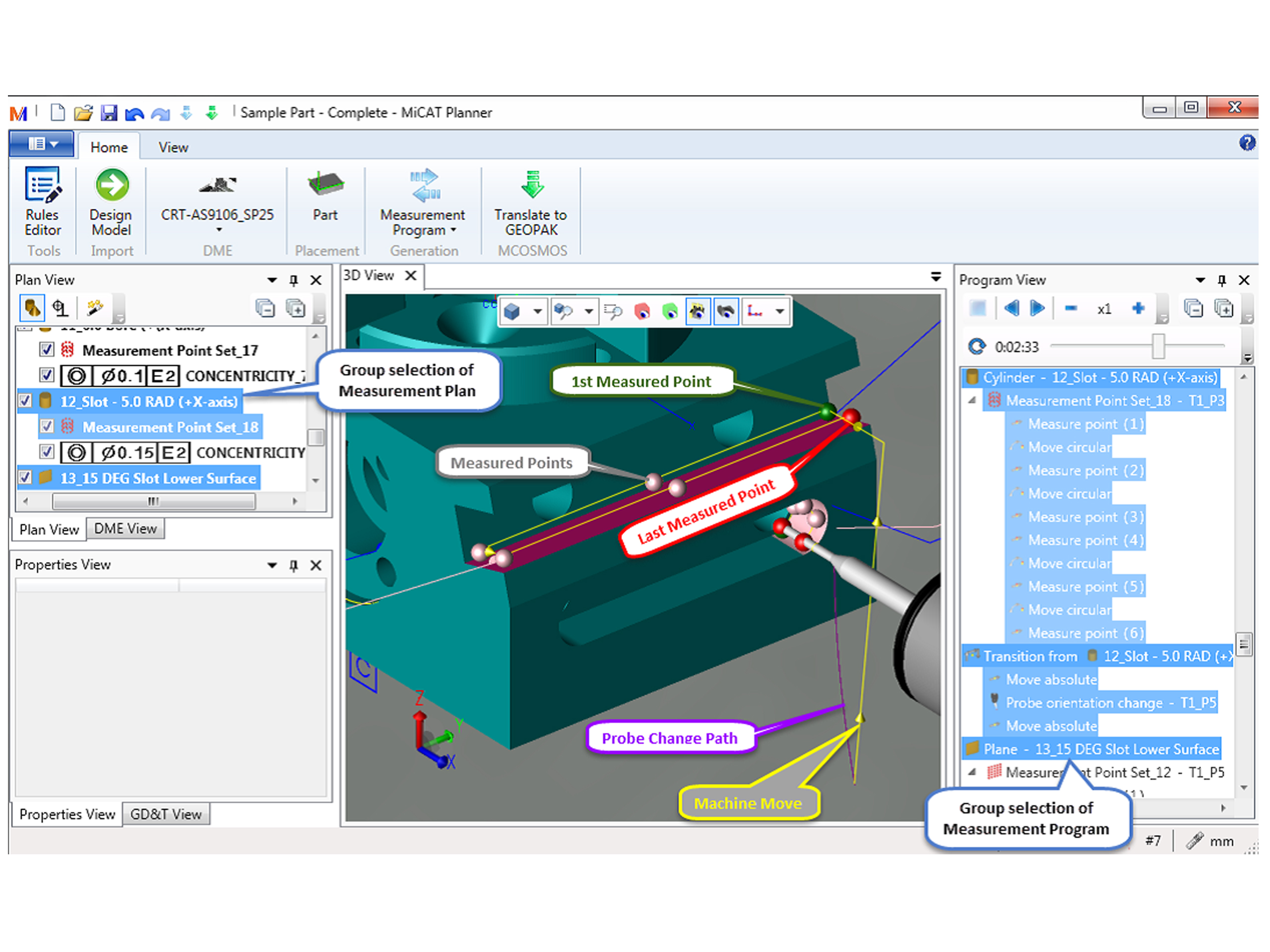

- Expert Part & Mold Design – We apply CAD and Design for Manufacturability (DFM) standards to ensure optimal functionality and efficiency.

- Smart Material Selection – Our team helps you choose the right resin for performance, durability, and cost from thousands of options that could be overwhelming.

- First Article Inspection & Quality Validation – Every part is validated through dimensional reports and FAIRs to ensure compliance before production.

- End-to-End Production Support – From prototypes to full-scale production, we ensure consistent part quality and mold performance through ongoing maintenance.

Plastic Injection Molding:

Precision Manufacturing Backed by Engineering Excellence

Colbrit now offers cutting-edge plastic injection molding services, combining expert engineering, high-quality tooling, and global manufacturing partnerships to deliver precise, cost-effective plastic components tailored to your most demanding applications.

- Expert Part & Mold Design – We apply CAD and Design for Manufacturability (DFM) standards to ensure optimal functionality and efficiency.

- Smart Material Selection – Our team helps you choose the right resin for performance, durability, and cost from thousands of options that could be overwhelming.

- First Article Inspection & Quality Validation – Every part is validated through dimensional reports and FAIRs to ensure compliance before production.

- End-to-End Production Support – From prototypes to full-scale production, we ensure consistent part quality and mold performance through ongoing maintenance.

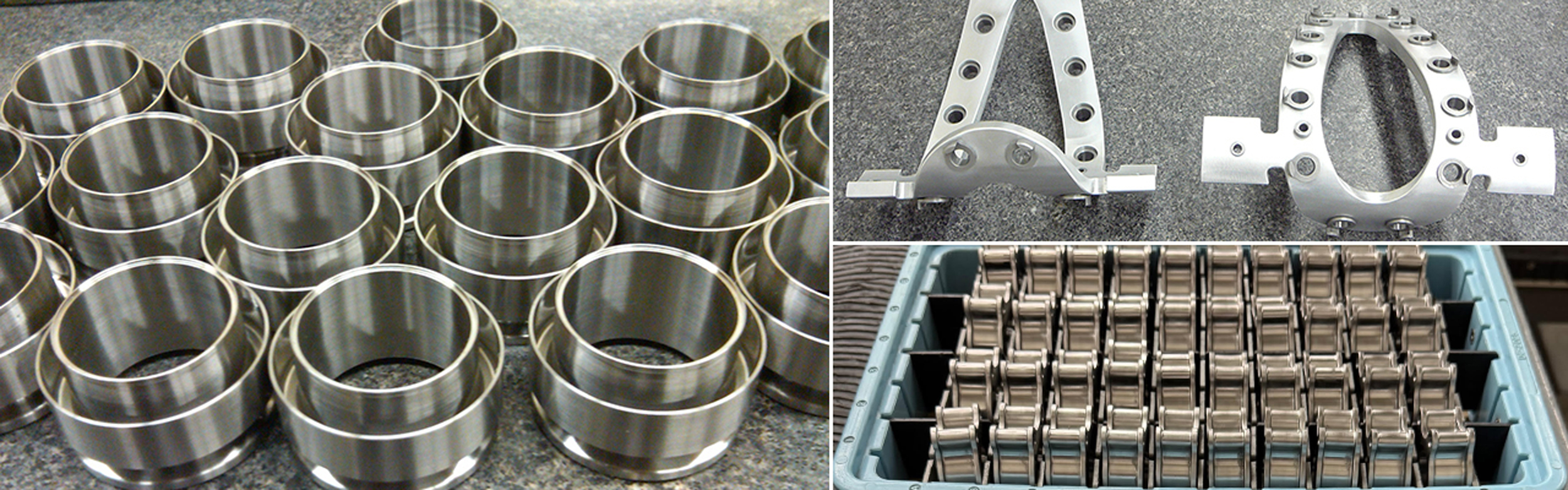

CNC Machining

We combine the latest CNC machining and turning processes with proprietary technology to deliver high quality, on-demand parts. Our typical tolerance accuracy ranges from +/- .0001″ to +/-.003″, depending on customer specs.

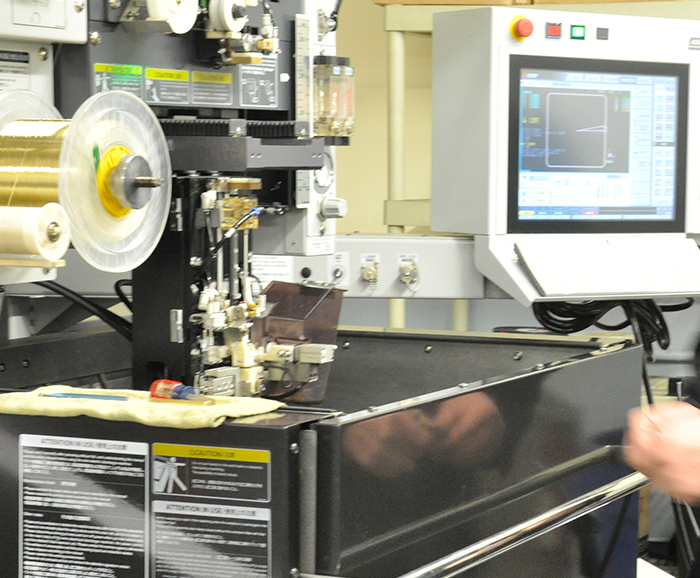

Wire EDM Machining

Four state-of-the-art Mitsubishi Wire EDM Machines form the basis for our EDM machining services. Whatever your requirement, if it can be wire EDM machined, we have your answer.

Wire EDM Machining

Four state-of-the-art Mitsubishi Wire EDM Machines form the basis for our EDM machining services. Whatever your requirement, if it can be wire EDM machined, we have your answer.

Swiss Screw Machining

Swiss screw machine services capable of producing parts with very tight tolerances, often down to ± .0001”. Machining is performed on a variety of materials including Stainless Steel, Titanium, Inconel, Brass, aluminum, Copper Alloys, and various Plastics and Composites.

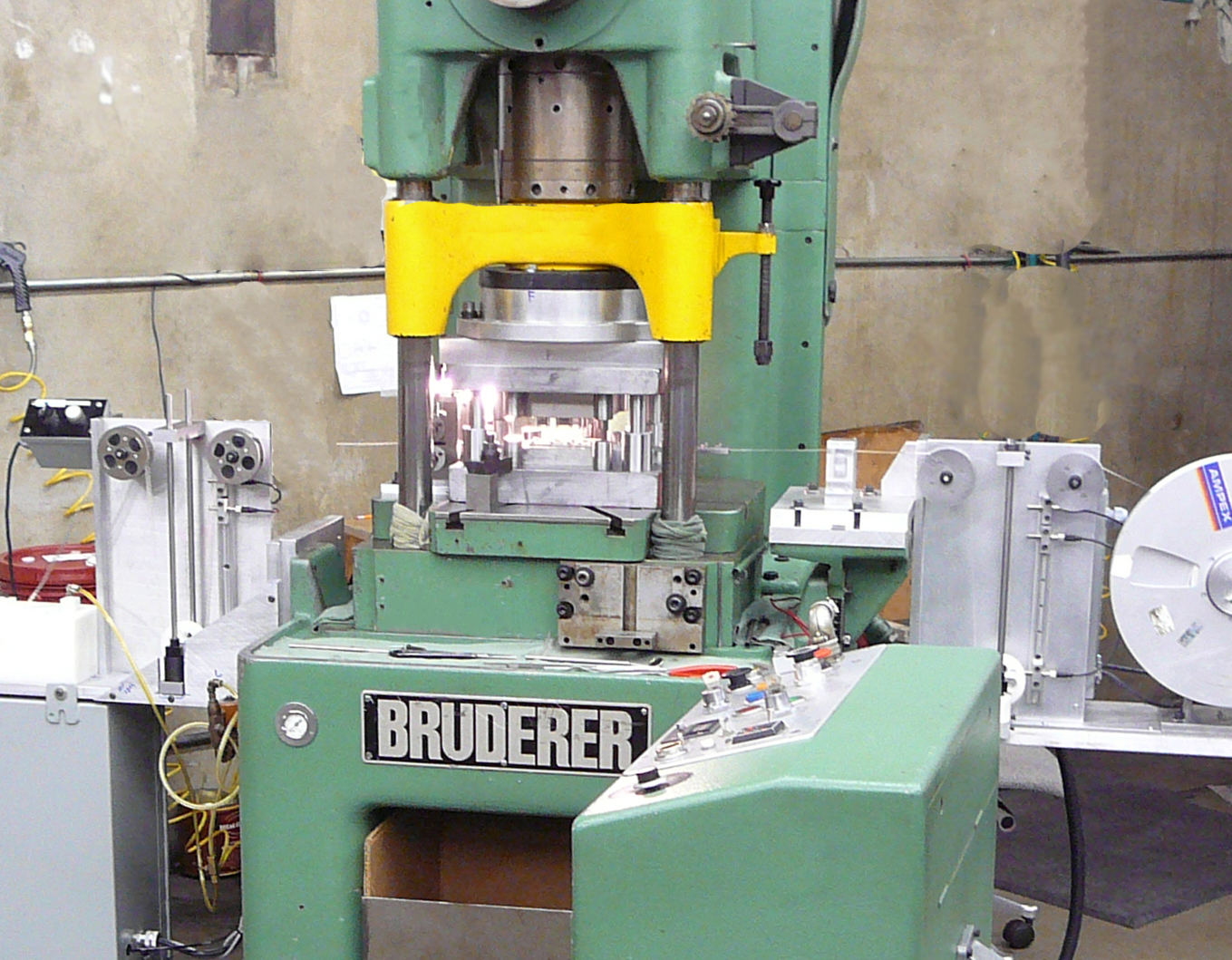

High-Speed and Custom Stamping

At Colbrit we provide a full range of stamping services. Our equipment includes punch presses ranging from 3-tons to 60-ton high-speed Bruderers. Our experience includes stamping of a variety of materials ranging from .002″ phosphor-bronze to .072″ copper alloy. No matter what your requirement, low or high volume, we can deliver.

High-Speed and Custom Stamping

At Colbrit we provide a full range of stamping services. Our equipment includes punch presses ranging from 3-tons to 60-ton high-speed Bruderers. Our experience includes stamping of a variety of materials ranging from .002″ phosphor-bronze to .072″ copper alloy. No matter what your requirement, low or high volume, we can deliver.

Tool and Die Design

If you have your own die manufacturing capability but need expert assistance in designing your dies, we can do the job. Our engineers are experts in designing highly efficient, long-lasting dies, whether simple or the most complex progressive dies. Our final design product can be provided in any form you require from hard copy to CAM-ready CAD files.

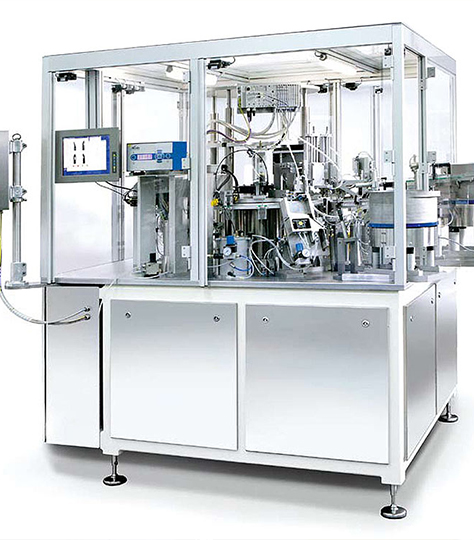

Production Process Automation

- Machining & Forming Solutions

- Vision Systems

- Machine Tending- Robotics

- Assembly Solutions

- Dispensing / Coating Systems

- Packaging Systems

- Electronic Connector Assembly

- Testing & Quality Inspection

- PLC & PC Programming

- Validation & Documentation

Production Process Automation

- Machining & Forming Solutions

- Vision Systems

- Machine Tending- Robotics

- Assembly Solutions

- Dispensing / Coating Systems

- Packaging Systems

- Electronic Connector Assembly

- Testing & Quality Inspection

- PLC & PC Programming

- Validation & Documentation

Markets Served

Since our founding we have been privileged to serve some of the world’s largest companies in such industries as:

- Aerospace

- Medical

- Automotive

- Telecommunications

- Computers

- Electronics